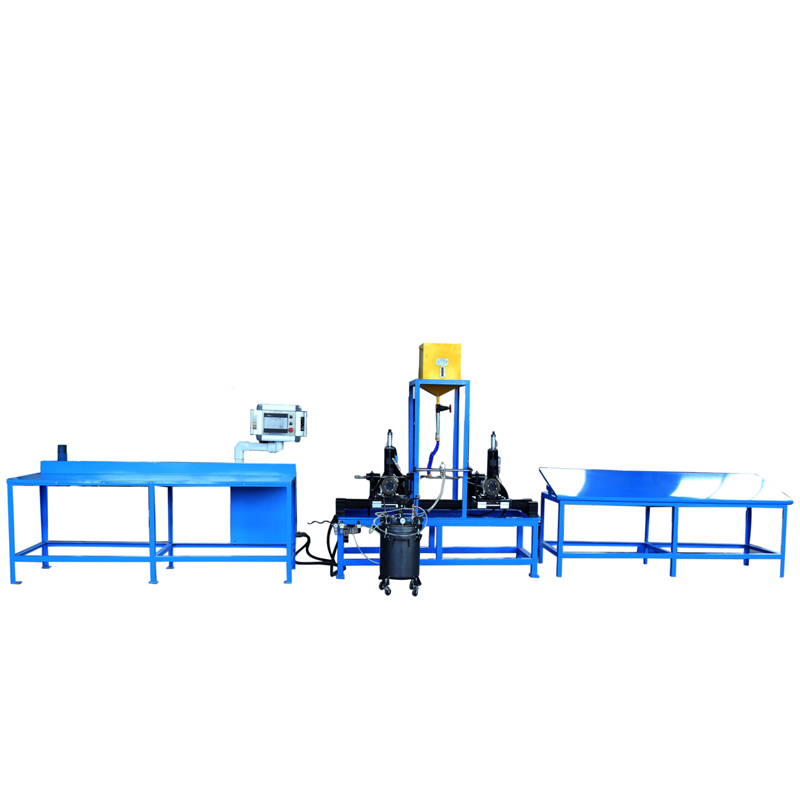

Product Introduction

XGPS-automatic forming production line for preformed armor rods

Electrical parameters:

1:Rated voltage: AC380V, 3P+PE3

2:Rated power: 400W

3:Rated current: 1.5A

4:Rated frequency: 50HZ

Electrical configuration:

1:Mitsubishi FX series PLC

2:WEINVIEW TK series 7-inch touch screen

3:Schneider or Siemens brand products are used for other auxiliary electrical appliances

Security configuration and human-computer interaction:

1:There is a manual operation interface on the touch screen to facilitate the operator to debug the machine.

2:Process parameters can be modified and set at any time on the touch screen.

3:Equipped with double travel switch to prevent glue spraying in wireless state

4:The oil spraying and sanding time is about 1Ms, which can be used for sanding products of different materials, different sizes and different rotation directions, and can be randomly matched with sanding discs, guide molds, etc.

Mechanical part:

1:The body steel plate is made of high-quality Q235 (Ma Steel)

2:The rack square tube is from Wuxi Liulong

3:Other mechanical parts are treated by 40Cr quenching and tempering

Standard parts:

1:All screws are grade 8.8 and made of polyurethane

2:The aluminum bearings use Harbin bearings

3:The seals are made in Taiwan.

4:The customized cylinder is from Wuxi Dachuan

5:The customized wire feeding wheel is made of polyurethane

Machine surface preparation (painting):

1:Painted with automotive paint (eagle paint)

2:The machine colors are light blue and yellow